Thermal printer labels are integral to a multitude of businesses, including warehouses, retail stores, healthcare facilities, and shipping companies. These labels cater to various needs, including barcoding, shipping, patient identification, and price tags. This comprehensive guide will delve into the intricacies of thermal labels, their compatibility with thermal printers like the Rollo USB and Rollo Wireless, and why they’re the go-to choice for many enterprises.

Types of Thermal Printer Labels

Two primary kinds of thermal labels are prevalent in the market: direct thermal labels and thermal transfer labels.

Direct thermal labels work through a heat-sensitive material that darkens as it moves beneath the thermal print head. As it doesn’t need ink, toner, or ribbons, this type becomes a cost-effective solution. Direct thermal labels are often used in scenarios where the label isn’t subjected to extreme conditions for long periods, as they may fade over time. Direct thermal labels are used by direct thermal printers.

Conversely, thermal transfer labels necessitate a thermal ribbon. The printer warms the ribbon, which in turn transfers the ink to the label, making the labels resistant to elements such as UV and chemicals. This feature makes them apt for long-lasting applications.

Materials of Thermal Printer Labels

The construction of thermal printer labels involves various materials, including paper and synthetic materials like polyester and polypropylene. The material choice is dictated by the label’s intended application and the environmental conditions it would face.

📄 Paper Thermal Printer Labels

Paper thermal labels are a common choice for shipping labels, inventory labels, and barcodes due to their cost-efficiency. They are ideal for indoor environments where they are sheltered from harsh conditions. However, they can be susceptible to damage from moisture, high temperatures, or rough handling. Over time, paper can become brittle or turn yellow, especially when exposed to sunlight or heat.

🏷️ Synthetic Thermal Printer Labels

When durability and resistance to tough conditions are paramount, synthetic thermal labels, made from materials like polyester and polypropylene, become the go-to choice. These labels resist the effects of high temperatures, moisture, chemicals, and UV light. As a result, they are excellent for industrial settings, outdoor environments, or situations requiring rough handling.

Synthetic thermal labels are tear-resistant, water-resistant, and can tolerate higher temperatures without compromising print quality. Plus, they resist fading when exposed to UV light. However, synthetic labels generally cost more than their paper counterparts and may not be the most eco-friendly option, as they take longer to degrade.

In summary, the choice of material in thermal printer labels significantly affects their quality, durability, and appropriateness for diverse environments and applications. It’s crucial to choose the right type based on your specific needs.

Usage Scenarios for Thermal Printer Labels

Thermal printer labels are employed in a wide range of sectors, from healthcare to logistics and retail. In shipping, labels ensure parcels arrive at the correct destination. In healthcare, patient identification wristbands are printed using thermal printers. Retail stores often use them for price tags and inventory control.

Exploring the Diverse Range of Thermal Printer Labels – Sizes and Shapes

Thermal labels have become a mainstay in a multitude of industries due to their versatility in terms of shape, size, and application adaptability. This flexibility allows businesses to find the perfect label to fit their unique needs, whether it be for shipping, product identification, barcoding, or any other purpose.

Understanding Thermal Printer Label Sizes

FSC-certified Rollo labels, renowned for their quality and environmental friendliness, offer a wide variety of label sizes to cater to different needs. A fundamental principle when it comes to label sizes is that the label paper size should correspond with the size of the label.

🏷️📐 4 x 6 Thermal Labels

For example, if you are working with 4×6 labels, which are commonly used for shipping labels due to their visibility and ample space for necessary information, you would need to use 4×6 label paper. This compatibility ensures that all the printed information fits perfectly on the label, maximizing legibility and adherence to shipping regulations.

🏷️📐 2 x 1 Thermal Labels

Another popular label size is the 2×1 barcode labels. As the name implies, these are typically used for printing barcodes, a common requirement for inventory tracking, retail tagging, and more. These smaller labels fit neatly onto product packaging without overwhelming it, and they are perfectly designed to accommodate a barcode and necessary product information.

✂️ Thermal Printer Label Shapes

Beyond sizes, thermal labels also come in a variety of shapes to better fit specific applications. Alongside the standard rectangular or square labels, FSC-certified Rollo labels also include circle labels on a roll. Circular labels are especially useful in applications such as highlighting specific information on products, sealing packages, coding, or even promotional branding.

🧲 Efficient Management with Rollo Label Holder

Regardless of the shape and size of your labels, proper storage and organization are crucial for efficient operations. The Rollo label holder can accommodate both rolls and stacks, making label management easier and more efficient. By holding your labels securely, this holder makes the printing process smoother and helps prevent any damage or wastage of labels.

Delving into Label Design and Customization with Rollo’s Label Designer

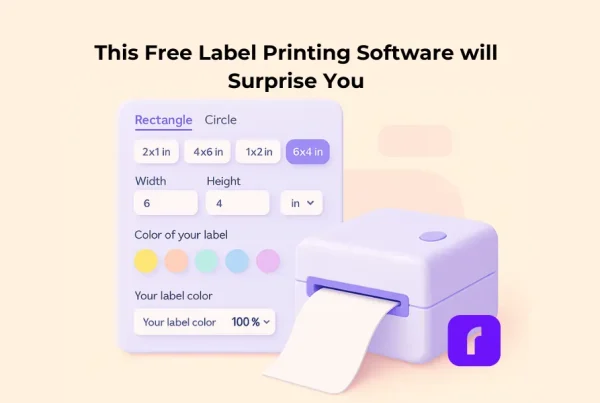

Designing and customizing your thermal printer labels is a crucial aspect of effective branding and communication. With software like Rollo’s Label Designer, you can streamline this process and ensure high-quality, consistent label designs that meet your specific needs.

When it comes to designing your labels, you can utilize Rollo’s Label Designer, a designated software for the purpose. Unlike platforms like Canva, Rollo’s Label Designer does not require you to adjust your label size later. This software has pre-configured settings for all standard label sizes, making it simpler to create the perfect label for your needs.

🎨 Tailored Solutions with Rollo Label Designer

Rollo’s Label Designer offers an intuitive, user-friendly platform specifically designed for label creation, making it a preferred choice over more general design platforms like Canva. It eliminates the need to adjust your label size later, a common inconvenience encountered in generic design tools. With pre-configured settings for all standard label sizes, including 2×1 and 4×6 labels, you can swiftly kickstart your label design process, ensuring your labels are in the perfect format from the get-go.

🎨 A Plethora of Design Choices

Rollo Label Designer goes beyond just basic label formatting, providing a range of design options to truly make your labels your own. The platform includes a diverse selection of templates, each with its unique style and message. Some popular templates include catchy phrases like “Good Vibes Loading“, “Treat yo’self“, “This is gonna be good“, “Hey thanks!“, “Happiness Delivered“, and “Thanks for shopping small“. These cheerful messages can add a personal touch to your labels, enhancing the unboxing experience for your customers.

🎨 Crafting Your Unique Label

If you want to create a unique label design, Rollo Label Designer provides a graphic interface where you can add various elements to your label. These include text, icons, shapes, barcodes, and images.

Let’s say you’ve decided to start with a blank canvas. First, you set the label size. This ensures your design fits perfectly within the label boundaries, preventing any crucial information from being cut off during printing.

Next, you can choose from a wide array of design elements. Want to add a compelling call-to-action or a product description? Add text. Need to insert a recognizable symbol or a logo? Pick from a range of icons or upload your own images. Looking to organize information in a visually appealing way? Incorporate shapes. Need to track your inventory or offer product details in a scan? Add a barcode.

🎨 Expressive Design Gallery

In addition to the design elements, Rollo Label Designer offers templates from its design gallery. This gallery is packed with pre-designed templates that add a touch of creativity and professionalism to your labels. Some examples include: “Thank you”, “Please recycle”, “Hooray for Mail Day”, “Packed with Recycled Materials”, “Winning”, “Shipped with Care”, and more.

💾 🖨️ Save or Print Directly

Once you’re satisfied with your design, you can either save it for future use or print it directly. This flexibility allows you to design your labels in advance and print them as needed, further streamlining your business operations.

Designing your thermal printer labels does not need to be a complex process. With Rollo’s Label Designer, you can efficiently design and customize labels to align with your brand and message. Whether you opt for a fun template or create a design from scratch, the Label Designer offers an abundance of choices, ensuring your labels are just as unique as your business.

🖨️ Printing Equipment: The Rollo USB and Rollo Wireless

The right thermal printer plays a significant role in the quality and efficiency of your label printing. The Rollo USB and Rollo Wireless printers are popular choices for their performance, ease of use, and compatibility with various thermal label types.

❓ Can you use any labels in a thermal printer Indeed, you can, but you need to ensure they are compatible. These Rollo printers can handle a variety of label sizes, and the adjustable guide allows easy switching between different label types. Hence, you can certainly use the FSC-certified Rollo labels with these printers.

Durability and Resistance of Thermal Printer Labels

A common question that often arises is, "Are thermal printer labels waterproof ❓" While the answer depends on the type and material of the label, many thermal labels are indeed water-resistant. Direct thermal labels may not have this characteristic, but many synthetic thermal labels are designed to withstand moisture, UV light, heat, and even chemicals. This makes them ideal for outdoor use, shipping, and harsh environmental conditions. However, the durability of these labels can also raise concerns like, "Do thermal labels expire ❓" or "Do thermal labels fade❓" The lifespan of a thermal label depends on the type of label and the conditions it's exposed to. Direct thermal labels, for instance, can fade over time, especially when exposed to heat or sunlight. In contrast, thermal transfer labels are more durable and resistant to fading.

Cost-effectiveness of Thermal Printer Labels

“Are thermal labels expensive ❓” is a common query among businesses. The answer, though, is subjective and depends on the type of label, quantity, and vendor. However, thermal labels are generally considered a cost-effective solution. This is primarily because thermal printers do not require ink or toner, reducing the overall running costs. Moreover, with discount thermal labels available from certain suppliers, businesses can achieve further cost savings.

Best Practices for Printing on Thermal Printer Labels

As you venture into the world of thermal labels and printers, it’s crucial to understand how to get the most out of your equipment. Here are some tips:

🪥 Ensure your printer is clean: A clean printer will yield better results and prevent issues like poor print quality or jamming.

☑️ Choose the right label: Your label should suit the application. Consider factors like exposure to heat, moisture, or sunlight, the required lifespan of the label, and if it needs to be resistant to tearing or abrasion.

⚙️ Use the right settings: Your printer should be set correctly for the type of label you’re using. This can include aspects like print speed and darkness.

✅ Test your prints: Before going ahead with large print jobs, print a test label to ensure the quality and settings are correct.

Environmental Impact of Thermal Printer Labels

It’s no secret that businesses are increasingly aware of their environmental impact. Thankfully, FSC-certified Rollo labels are responsibly sourced and managed, making them an environmentally friendly choice. Still, it’s crucial to understand how to properly dispose of or recycle these labels to minimize waste.

Regulations and Standards

In some industries, there are specific regulations and standards for label printing. For example, the shipping industry has specific requirements for the format and information on shipping labels. Similarly, in healthcare, patient identification labels must meet certain privacy standards. Ensure your thermal labels and printing practices comply with all relevant regulations in your industry.

Thermal Printer Label Software

When it comes to creating your labels, the right software can make all the difference. Rollo’s Label Designer is designed specifically for this purpose, and you can use it to create all kinds of labels, from shipping labels with Rollo Ship to barcode labels.

How do I make labels for my thermal printer? With the Rollo Label Designer, it’s straightforward. Simply choose the size of your label, then add the text, images, or barcodes you need. The software is intuitive and easy to use, even for beginners.

Troubleshooting Thermal Printer Label Issues

Thermal printers are generally reliable, but like any technology, they can sometimes face issues. A common problem is the thermal labels turning black. This issue can occur when the print head overheats, causing the entire label to darken. It’s best to turn off the printer and allow it to cool before attempting to print again.

Do thermal labels need ink❓One of the advantages of thermal printers is that they don’t require ink or toner. However, for thermal transfer printers, you’ll need a thermal ribbon to print the labels.

What about fading? How long do thermal stickers last❓ Direct thermal labels may fade over time, particularly when exposed to heat, light, or harsh environmental conditions. If your labels are fading too quickly, it might be worth considering a different type of label or storing them in a cooler, darker place.

Looking Forward: The Future of Thermal Label Printing

Just like any other technological field, the world of thermal printing is in a state of constant progression. Upcoming trends are steering towards more environmentally-friendly label solutions, improved resilience to environmental factors, and breakthroughs in printing technology. As these developments unfold, the efficiency and versatility of thermal printing are anticipated to reach new heights, presenting a wider range of options for businesses big and small.

Wrapping Up: The Power of Thermal Printer Labels

Thermal printer labels have carved their indispensable niche in numerous businesses, delivering a robust, budget-friendly, and adaptable solution to diverse labeling necessities. Comprehending the variety of thermal labels, pinpointing the perfect ones to cater to your requirements, and mastering the optimal use of your thermal printer empowers you to leverage this technology to its fullest.

Whether you’re pondering over incorporating thermal printers and labels into your business, or seeking to enhance the efficacy of your current arrangement, we hope this guide arms you with the insights needed to make well-informed decisions.

Remember, the magic lies in selecting the apt thermal labels and printer tailored to your specific demands. With options such as the Rollo USB and Rollo Wireless printers and an array of Rollo label choices at your disposal, you’re well on your way to fulfill your business requirements.

From thermal label rolls to thermal label paper, thermal stickers to thermal printer stickers, and direct thermal printer labels to discount thermal labels – the domain of thermal printing is expansive and diverse. At the end of the day, it all boils down to discovering the ideal solution catered to your particular needs.

Here’s to a fruitful printing journey! 💜

Follow Rollo on:

Frequently Asked Questions about Thermal Printer Labels

🏷️📐Q: What size labels for a thermal printer?

Short Answer: Depending on your needs.

A: Depending on your specific use case, thermal printers accommodate a variety of label dimensions, from petite barcode labels to sizable shipping labels. Common sizes are 2×1 inches for barcodes and 4×6 inches for shipping labels. Nevertheless, the precise size suitable for your needs would be determined by the purpose and the printer’s capabilities.

⌛ Q: How long do thermal prints last?

Short Answer: Varies with label type and environmental factors.

A: The durability of thermal prints is influenced by the nature of the label and the environmental conditions it is subjected to. Direct thermal labels may diminish over time, particularly when exposed to heat or sunlight. Conversely, thermal transfer labels, especially those printed on synthetic materials, have a longer lifespan and can withstand harsh conditions for several years without fading.

⚫ Q: Do thermal labels turn black?

Short Answer: Yes, under specific conditions.

A: Thermal labels are susceptible to turning black when subjected to high heat levels. This is due to the heat-sensitive nature of thermal printing, which uses heat to create the printed image on the label. Overheating of the printer’s print head can also result in the darkening of the entire label.